How are suspended slabs built?In such a case, you have what is known as a cold joint Next days concrete will not stick well with the old concrete Apart from being a weak joint which can be structurally damaging, (especially if it is in a shear zone), Cold joints in a terrace Quote (Houseboy) 1) Put some shear studs on top of the beam 2) Turn the slab down at the beam such that the top of the beam is encased 3) Weld some little pieces of angle or bent rebar to the top of the beam 4) Install some vertical bolts in the top flange that project into the slab

Suspended Garage Slab From Design Build Specialists Steel Concepts

How to make a suspended concrete slab

How to make a suspended concrete slab-EXCAVATING THE AREA FOR THE CONCRETE SLAB Move the formwork out of the way and dig out the area for the slab to the required dimensions Allow an extra 5 cm of depth for a bed of crusher dust or road base under the slab Place the formwork back in position and ensure that it is level using a spirit level8 Once the slab is square we pound a nail in each corner and run a string around the perimeter of the slab forms We use the string to straighten the forms while we stake the rest of the boards Hammer a stake about every 4 to 5 feet to keep the forms straight when you pour the concrete for the slab

Formdeck By Formcraft Pty Ltd Archello

DO pond cure concrete slabs Pond curing is another great way to cure concrete, and the process is just as it sounds You form temporary berms around a new concrete slab A house concrete slab might be thicker than a slab for a shed It will require more concrete and more labour, so the concrete slab cost per m2 will be higher How big is the job? Posted I am trying to create garage foundation walls to support 8" preformed cement slabs for a room under the garage The manufacturer recommends a 12" foundation shelf inside the stem walls to suspend the slab and then be able to pour the 4" garage floor slab on top I am struggling finding a way to create this type of

Pour the concrete in small sections Spread the concrete by moving the chute back and forth and by having the driver pull forward as you go Once the truck has reached the end of a section, spread the concrete out evenly, and a touch higher thanPrecast suspended slabs are constructed by pouring the slab in a formwork on the ground and then lifting the slab into its suspended position in the structure Formwork is installed on top of the struts and beams Reinforcement is assembled on top of the formwork Concrete is then poured into the formwork Check the corner intersection of beams and column if not congested Ensure aggregates may pass through during concrete pouring Fix slab bottom bars Arrangement shall be short span at the bottom and longer span above the short span Check clean spacing of reinforcement from shutter Proceed with installation of plumbing sleeves and electrical services

Steps Involved in Pouring Concrete over Existing Concrete Slab Step 1 Cleaning Old Concrete Surface Sweeping dirt's debris over the existing concrete slab will allow bonding to take place This includes removing sand, dead leaves, and gravel One of the best tools that can be clean all the debris out of crack is a stiffbristle broomSlab R‐Value Table Insulation and Fenestration Requirements by Component E ClimateZone Slab R‐valued 4 10, 2 ft 5 10,2 ft 6 10,4 ft 9 d R‐5 shall be added for heated slabs Heated slab slab‐on‐grade construction in which the heating elements are in contact with, or placed within or under the slabThey don't have any real design guidance concerning deflection or crack control or how the tolerances can be different between the concrete and the steel As a contractor, therefore, don't be afraid to talk to the engineer about all this

This Is Everything Inside A Suspended Slab That A Lot Of People Do Not See We Have A Concrete Beam To The Middle Left Han Storey Homes Ideal Home Construction

Structure Suspended Slab Home Building In Vancouver

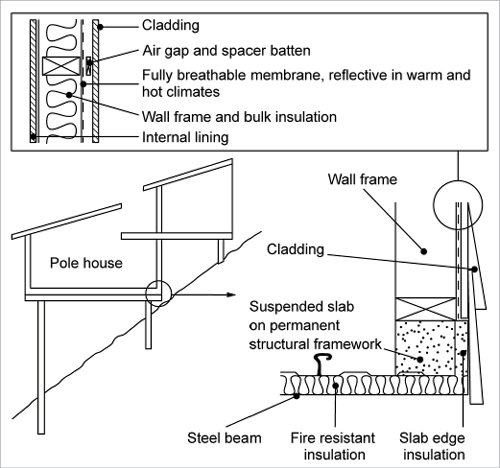

When pouring a suspended slab over an existing concrete floor, a layer of rigid insulation is installed, and the tubing can be attached to the old slab with tubing straps by power nailing directly into the concrete with a ram set Or, wire mesh can be anchored to the concrete in the same manner and the tubing can be attached to the mesh Polishing of suspended slabs usually takes place much longer after the concrete was placed, which increases concrete strength due to extended curing The polishing contractor could be dealing with Suspended slabs are upper floor slabs that are not in direct contact with the ground and form the roof or the floor above the ground level They usually form the upper stories house floors but can also be laid on top of a prebuilt wall to form a floor Concrete slabs come in many forms and can be used to provide great thermal comfort

Concrete Sweating Guide On How To Stop Concrete From Sweating

Precast Garage Floor Forterra

The concrete is basically just flooring material and does not support its own weight This has all the advantages of concrete as a surface durability, hardness, you could bond tile to it, etc But it does not rely on the concrete for actual structural strength of the building, as a metalpan would in a commercial setting1 Precast concrete Unlike onsite concrete pouring, a leading manufacturing approach is used to produce highquality 2 PourinplaceAnother recent development in pouring concrete structures such as slabs is to add polypropylene fibers to the concrete, which then form a threedimensional mesh to reinforce the slab The chemicalmechanical bond the fibers form with the concrete can be superior, depending on what the structure is used for, to rebar reinforcement

Concrete Placement Concrete Construction Perth Westcon Contracting

Guidelines For Poured Concrete Over Corrugated Metal Home Improvement Stack Exchange

Labor Cost For Concrete Slab The cost of labor to pour concrete is $45 per hour There can also be a delivery fee of $60 To have concrete poured and finished, it will cost $252 to $260 per square foot for the labor, and $2 to $357 per square foot for the concrete itself Concrete slabs are poured either off or on the job site We build suspended slab porch decks all the time and use the space below typically as unconditioned "cellar" storage We typically pour / 8" at the house and fall to / 7" towards the landscaping over a typical span of 7 feet We ledge the concrete slab on the foundation at the house by holding the framing towards the inside and we pourI have answered this question a 1000 time in my years of being a structural engineer You can remove the forms at 70% of design strength Usually 3 days If it goes 7 you will at some point have trouble with the 28 day breaks Trust me I have seen

Suspended Slab Suspended Concrete Slab Cement Slab

The New Zealand S First Passive House Concrete Floor Slab Second Pour

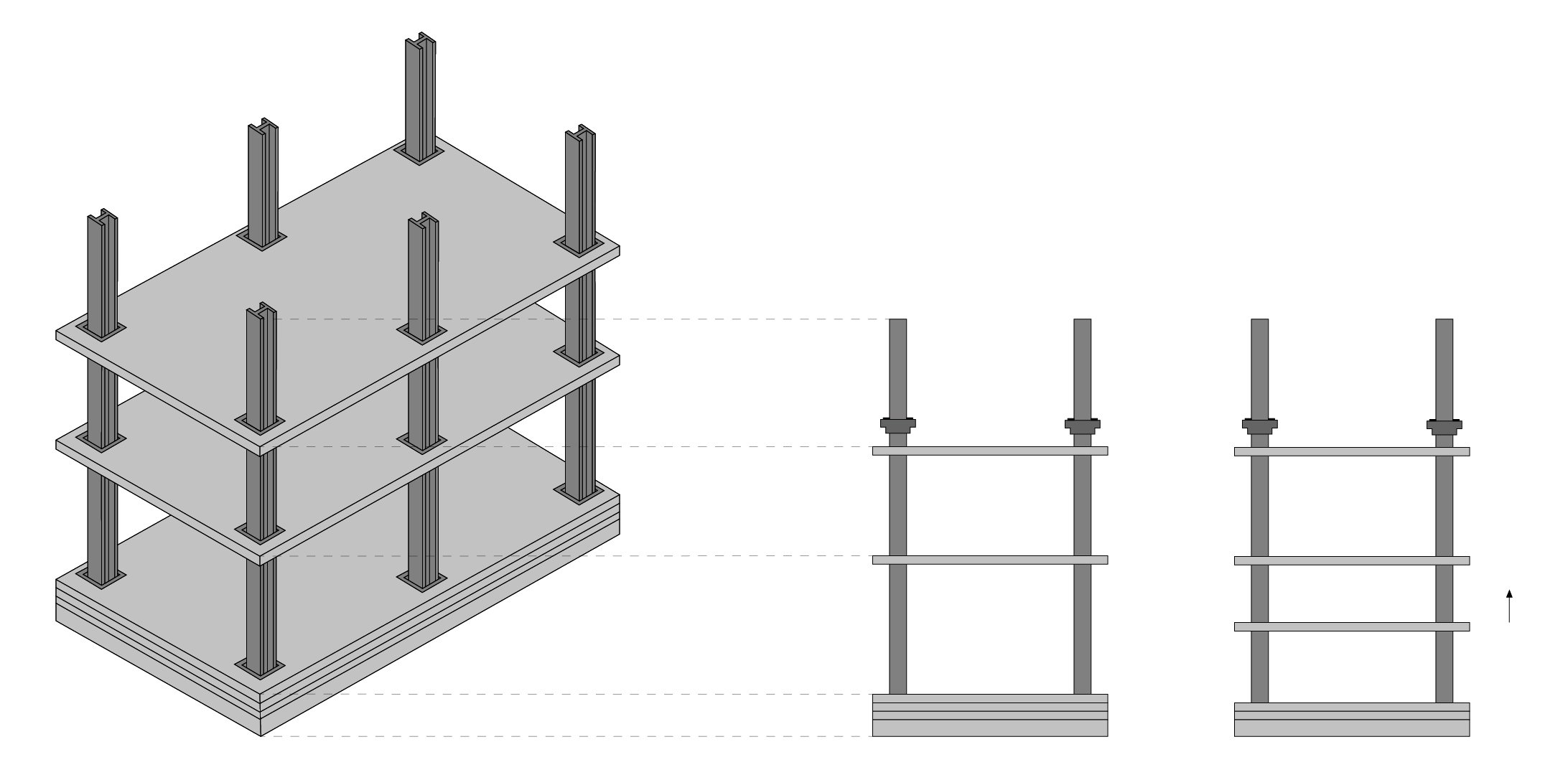

Pouring interior concrete slab over existing, cracked concrete slab 4 Answers I am turning part of my carport into a new living room I am going to pour a concrete slab about 4 inches thick over the existing carport floor which is a concrete slab The existing slab has a few cracks, the largest of which is about an 1/8inOnly 6"8" concrete topping required Using a composite steel and concrete design the floor slab can be thinner than conventional residential suspended slab systems This results in a cost savings in concrete of 2550% Slab, Beam and Foundation Concrete Pouring Pouring concrete into the slab is common It is usual After the reinforcements work is completed and all the necessary approvals are taken, pouring of concrete can be done Concrete can be poured into the slab by using the pump car or manually concrete can be taken into the slab Concrete Pouring in Piles

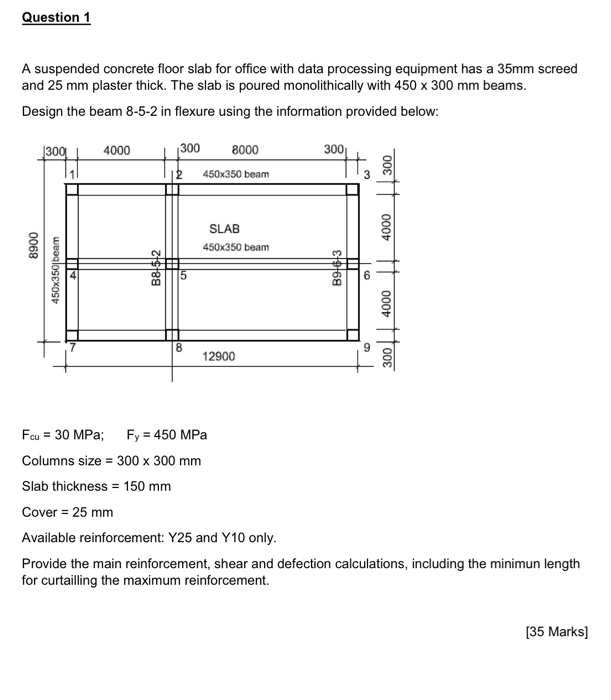

Question 1 A Suspended Concrete Floor Slab For Office Chegg Com

Concrete Slab Wikipedia

The following details the stepbystep process for pouring a concrete slab from beginning to end Safety First Designate and Prep Area Create Concrete Forms and Level Grade Install Rebar Pour the Concrete and Spread Screed, Float, and Trowel Round SlabSuspended concrete slab is referred to a cement slab that is not in contact with the ground This type of concrete slab construction requires different concrete slab design from the one we normally see that is cast on the ground The most common application of suspended slab in residential construction is used at garage floor where below the garage floor is a storage room orConcrete slabs can weigh more than 800 pounds and are at risk for tipping, shifting, and falling on those around themAlmost every job that you can have as a construction worker carries a possibility of working with concretewhich ultimately increases your chances of sustaining serious injuriesConcrete DangersConcrete construction accidents

Structure Suspended Slab Home Building In Vancouver

Constructing A Suspended Porch Slab Doityourself Com Community Forums

Engineers who design slabs on metal deck aren't thinking about the contractor;Step 7 Pour or place readymix, or mixup concrete and pour or place Step 8 Screed or float the concrete level and let it setup Step 9 Edge, groove, and finish the surface as desired Step 10 Cover if necessary and allow to cure for 48 hours or more before removing forms Pouring Concrete Next to Existing ConcreteThe cost of a concrete slab generally falls between $3 and $10 per square foot, depending on factors like the thickness of the slab and whether frost walls are included or the slab is floating For a 500 to 1,000squarefoot house, you can expect to pay around $5,318 for your slab When making pricing decisions — such as choosing between a 4inch, 5inch or 6inch slab — factor

Suspended Slab And Beams Method Of Construction Constructupdate Com

Pouring A 50 Ton Elevated Concrete Porch Slab Youtube

You can pour slabs in sections, you just need to pin them together with rebar so that they stay in alignment This is how concrete road surfaces are done Malcolm is right too, if you have your slab not flat or not level everything else becomes a problem since you're constantly having to try to compensate for the uneven slab Here is the method statement of Slab on Grade preparation and concrete pouring 1 Title 2 Purpose and scope The purpose of this method statement is to explain the proper procedure on how to prepare and cast slab on grade or any horizontal element or member including fixation of steel reinforcement, MEP embedment's, fixing of shutter etcThe size of the job can drastically change the concrete slab cost, because travel, setup and other timeconsuming details need to be factored into the quote

Concrete Slab Abis

The New Zealand S First Passive House Concrete Floor Slab Second Pour

Pouring a Structural Slab Over Living Space The nested ribs of the decking add integral beams to the concrete, strengthening the slab The slab needs to slope 1/8 inch per foot, so a sloped ledge was designed into the exterior foundation walls for the steel decking to rest onConcrete which is moist cured for 7 days is about 50% stronger than uncured concrete Water curing can be done after the slab pour by building dams with soil around the house and flooding the slab The enclosed area is continually flooded with water Ideally, the slab could be water cured for 7 Method of Statement template for Suspended Slab explain slab arrangement, formwork, concrete pouring, concrete testing, dismantling scaffolding, training and

Construction Fun Facts Pouring A Concrete Yard Exaktime

Hanna Consulting Pouring The Suspended Concrete Slab Together With The In Situ Structural Concrete Beams Facebook

For one thing forming suspending slab take time and a lot of labor On top of that those forms have to remain in place until the concrete reach its strength before considered safe to remove which can take up to 4 weeks or moreTo reinforce a 4" concrete slab or driveway with steel rebar, determine the grid spacing and rebar size – #3 or #4 in a 12" to 18" grid Use 2" rebar chairs to support the rebar in the center strata of the pad Overlap joints by a minimum of 12" for #3 and 15" for #4, bind with wire ties, and keep the steel 3" back from the Is this episode of concrete ninja will you do a job with Tim and the boys for Jeff Lennox It is a 300 m² suspended slab one story high some of that is over

Construction Joint In Slabs The Structural World

Forming The Elevated Slab And Curbs Fine Homebuilding

Suspended slabs For a suspended slab, there are a number of designs to improve the strengthtoweight ratio In all cases the top surface remains flat, and the underside is modulated A corrugated slab is designed when the concrete is poured into aConcrete slabs also results in flexural crack formation and possible failure Cracking in concrete can be reduced significantly or eliminated by observing the following practices 1 Use proper subgrade preparation, including uniform support and proper subbase material at

Structure Suspended Slab Home Building In Vancouver

1

How To Build A Custom Home Part 18 Concrete Slabs Basement And Garage Floors The Bold Company

Structure Suspended Slab Home Building In Vancouver

Monolithic Definition Monolithic Footing Monolithic Slab Foundation Advantages Disadvantages Of Monolithic Slab Foundation Monolithic Slab

How Are Suspended Slabs Built Build

Formdeck By Formcraft Pty Ltd Archello

5 Things To Look For When Inspecting A Suspended Concrete Slab

Suspended Garage Slab From Design Build Specialists Steel Concepts

5 Things To Look For When Inspecting A Suspended Concrete Slab

Concrete Slab Wikipedia

Radiant Floor Heating Tubing Installation Methods Radiantec

Suspended Garage Slab From Design Build Specialists Steel Concepts

Structure Magazine Concrete On Metal Deck

Suspended Slab

Jj Duffy Demolition Pouring Concrete For Suspended Floor Slabs All Civil Works Completed By Jjd

Pouring Suspended Concrete Porch Cap Expansion Joint Needed On House

Suspended Concrete Slab Project On Commercial Drive

New Home Pouring A First Floor Suspended Slab Youtube

Cornerstone Building Civil Engineering Suspended Slab With Removable Formwork Ready For Concrete Pouring Looking At The Example In The Image The Steel Bars Are There To Withstand And Counteract The

Suspended Concrete Slab Suspended Slab Cement Slab

The New Zealand S First Passive House Concrete Floor Slab Second Pour

Concrete Floor Slab Construction Process The Constructor

Why Polishing Suspended Concrete Slabs Is More Likely To Disappoint Customers For Construction Pros

How To Specify Suspended Slabs On Metal Deck Concrete Construction Magazine

Blog Archives Neoterra

Guidelines For Poured Concrete Over Corrugated Metal Home Improvement Stack Exchange

Concrete

Pouring The Slab And Framing The Walls Greenbuildingadvisor

Concrete Floor Slab Construction Process Eplan House

Structure Suspended Slab Home Building In Vancouver

Placing Finishing Warehouse Slabs On Metal Deck For Construction Pros

Monolithic Slab Monolithic Monolithic Concrete Slab Diy Concrete Slab Cement Floors Diy Concrete Slab Pouring Concrete Slab Slab

A Primer For Pouring Concrete Powerblanket

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Suspended Garage Slab From Design Build Specialists Steel Concepts

3

Watershed One Demostration House Floor Slabs And Foundations Watershed Materials Technology For New Concrete Blocks

Final Suspended Slab Youtube

Pouring A Structural Slab Over Living Space Protradecraft

How To Prevent Cracks In Post Tensioned Concrete Slabs Pro Builder

Pouring A Suspended Slab Youtube

Suspended Floors

Moisture Barrier For Concrete Floor Guide

Concrete Slab Wikiwand

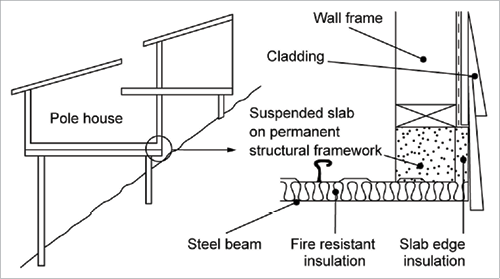

Concrete Slab Floors Yourhome

Suspended Garage Slab From Design Build Specialists Steel Concepts

Concrete Slab

5 Things To Look For When Inspecting A Suspended Concrete Slab

Constructing A Suspended Porch Slab Doityourself Com Community Forums

Concrete Suspended Beam And Slab Construction Process Steel Rebar Reinforcement Placement Formwork Youtube

Suspended Garage Slab From Design Build Specialists Steel Concepts

Exclusive Residence Suspended Slab Extension Concrete Pour Youtube

Suspended Slab Neoterra

Concrete Slab Floors Yourhome

Concrete Slab Wikiwand

Shoring Support For Concrete Slabs Efco Formwork Solutions

Concrete Slab Wikipedia

Suspended Concrete Slab The Labbe House Project

Garage Foundation Foundation Footing Suspended Concrete Slab

Concrete Slab Floors Yourhome

Suspended Slab Concrete Pour Youtube

Pour Strip In Concrete Slab Rebar People

Concrete Slab Floors Yourhome

5 Things To Look For When Inspecting A Suspended Concrete Slab

Suspended Ground Floor Construction Mezzanine Floor Supplier And Installers Prestressed Concrete

Concrete Slab Construction Pouring A Concrete Slab Cement Floors

Pouring Concrete Suspended Slab Gallery Tullipan Homes

One Way Concrete Joist System Concrete Slab Metal Deck Steel Frame Construction

What S Possible With Suspended Slabs On Metal Deck Concrete Construction Magazine

Concrete Floor Designing Buildings Wiki

Concrete Floor Slab Construction Process The Constructor

5 Things To Look For When Inspecting A Suspended Concrete Slab

Pouring Concrete Slab Under Suspended Resilient Tie Block Flickr

Quad Deck Insulated Concrete Forms For Floors And Roofs

Forming Concrete Suspended Slabs Youtube

Suspended Concrete Slab Suspended Slab Cement Slab

Concrete Slab Floors Yourhome

Building An Extension 3 Suspended Beam Block Floor Youtube

Structure Suspended Slab Home Building In Vancouver

Lift Slab Construction Wikipedia

Suspended Garage Slab From Design Build Specialists Steel Concepts

How To Pour A Perfect Concrete Slab Powerblanket

What S Possible With Suspended Slabs On Metal Deck Concrete Construction Magazine

0 件のコメント:

コメントを投稿